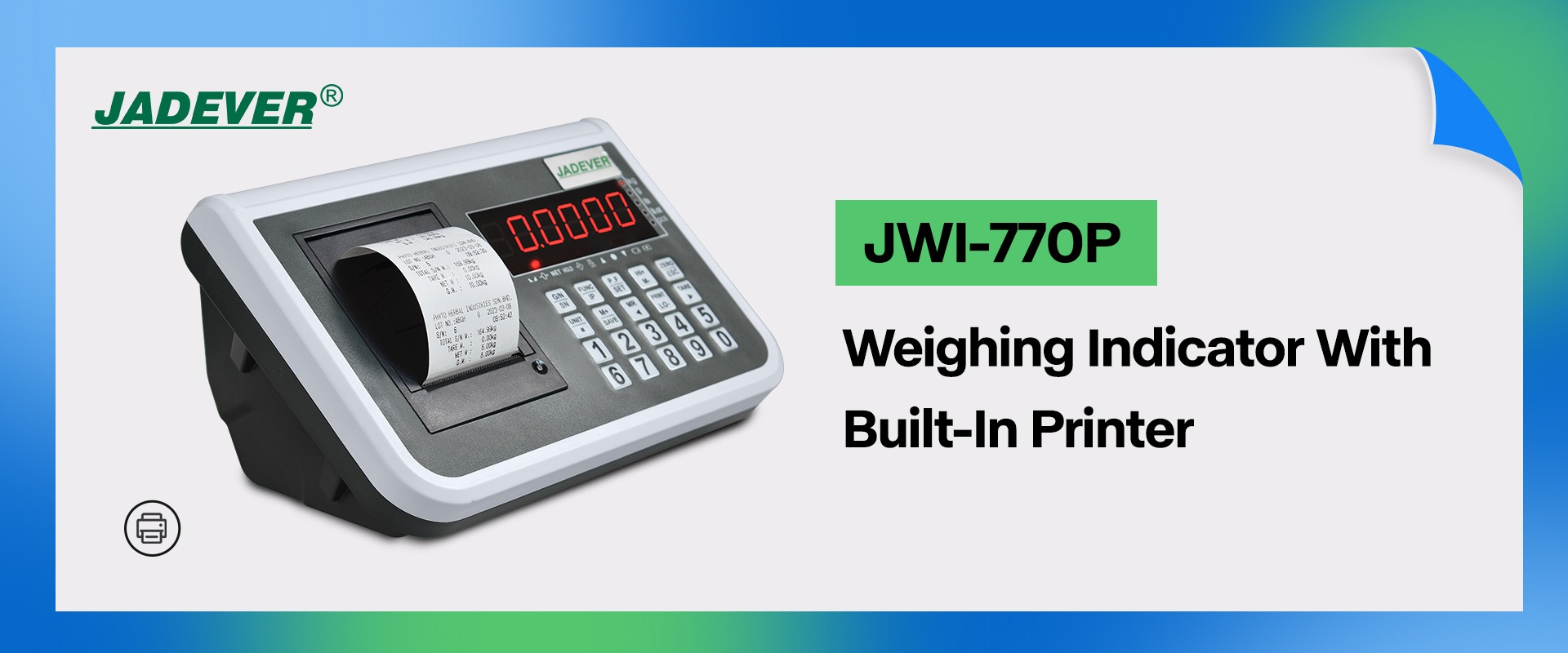

في الإنتاج الصناعي الحديث والمعاملات التجارية، لطالما شكّلت كفاءة عملية الوزن ودقة تسجيل البيانات تحديًا للممارسين. غالبًا ما تتطلب مؤشرات الوزن التقليدية توصيلًا إضافيًا بالطابعات، مما لا يشغل مساحة فحسب، بل يُسبب أيضًا أخطاءً في نقل البيانات بسبب مشاكل توافق المعدات. الآن، جاديفير JWI-770P يعمل مؤشر الوزن المطبوع المدمج على كسر نقاط الضعف في الصناعة بتصميم مبتكر، حيث يجمع بين الوزن الدقيق والطباعة المريحة في واحد، مما يوفر حل وزن ذكي لمختلف الصناعات.

أبرز ما يميز جاديفير JWI-770P طابعة حرارية دقيقة مدمجة. لا حاجة لتوصيل أجهزة خارجية، ما عليك سوى تشغيلها لطباعة بيانات الوزن فورًا. سواءً لوزن المنتجات الطازجة في المتاجر، أو فرز البضائع في المستودعات، أو تحديد نسب المواد الخام الصناعية، يُمكنها إنشاء ملصقات وإيصالات واضحة فورًا. تدعم الطابعة المواد الاستهلاكية بعرض 50 مم مع نطاق طباعة فعال يبلغ 48 مم، مما يُلبي احتياجات طباعة الملصقات والإيصالات التقليدية، ويضمن تسجيل جميع بيانات الوزن بصريًا.

من حيث تصميم مزود الطاقة، يتميز جهاز JWI-770P بمرونة عالية. فهو يدعم وضعي الشحن والتوصيل بالكهرباء: بطارية الليثيوم المدمجة 7.4 فولت/5000 مللي أمبير/ساعة تكفي للعمل لمدة 40 ساعة تقريبًا عند شحنها بالكامل، مما يُمكّنها من التعامل بسهولة مع انقطاعات التيار الكهربائي المؤقتة أو العمليات الخارجية. كما أنه متوافق مع نطاق واسع من جهد الدخل يتراوح بين 100 و240 فولت، ويُنتج تيارًا ثابتًا بقوة 9 فولت/1 أمبير لضمان التشغيل المستمر لساعات طويلة. هذا التصميم "المزدوج" يحل تمامًا مشكلة انقطاع عمل مؤشرات الوزن التقليدية الناتجة عن عدم استقرار مصدر الطاقة.

كجهاز وزن للإنتاج الحديث، لا يُعدّ جهاز JWI-770P مجرد أداة وزن، بل مركزًا لإدارة البيانات. يدعم تخزين مجموعات متعددة من معلومات المواد، والتي يمكن تعديلها وحفظها مع المتغيرات المرتبطة بها، مثل الرقم، واسم المنتج، والمواصفات، وعتبات الحد الأقصى والأدنى، ووزن الطرد، وغيرها. يمكن للمستخدمين البحث بسرعة عن رموز رقمية مكونة من 6 أرقام وتبديلها باستخدام مفاتيح رقمية، مما يُحسّن بشكل كبير من كفاءة مخزون المستودعات وخط الإنتاج. جديد (التجميع).

فيما يتعلق بإخراج البيانات، يدعم الجهاز طباعة الملصقات المخصصة، ما يسمح بإخراج بيانات رئيسية مثل الوزن، والرقم التسلسلي، والتاريخ والوقت، ورقم الدفعة، ومعلومات المواد حسب الحاجة. والأهم من ذلك، يمكن نقل محتوى الطباعة بشكل متزامن، باستخدام صيغة تبادل بيانات خفيفة الوزن، للتوافق بسلاسة مع التطوير الثانوي لتطبيقات الخادم وتكامل المنتجات، مما يوفر دعمًا أساسيًا لتكامل أنظمة تخطيط موارد المؤسسات (ERP) وتتبع بيانات سلسلة التوريد. بالإضافة إلى ذلك، يدعم الجهاز أساليب إدخال مخصصة مثل التعرف على الماسح الضوئي، وقراءة وكتابة المواد السحابية/المحلية، مما يجعل إدارة البيانات أكثر مرونة.

فيما يتعلق بأداء وزن القلب، يُلبي جهاز JWI-770P معايير القياس الصناعية بدقة عرض خارجية تبلغ 1/30000 وخطأ لاخطي بنسبة 0.003% في المقياس الكامل. يستخدم الجهاز طريقة تحويل Δ-Σ من تناظري إلى رقمي بدقة داخلية تصل إلى 700,000 وتردد تحويل يبلغ حوالي 10 مرات في الثانية، مما يضمن بيانات مستقرة وموثوقة أثناء الوزن الديناميكي. بفضل حساسية الإدخال البالغة 0.2 ميكروفولت/القسمة ونطاق جهد الإدخال الواسع الذي يتراوح بين -2 و20 ملي فولت، بالإضافة إلى جهد إثارة خلية الحمل +5 فولت تيار مستمر، يُمكنه التكيف مع مختلف مواصفات خلايا الحمل لتلبية احتياجات القياس في مختلف النطاقات.

في التفاعل بين الإنسان والحاسوب، تم تجهيز الجهاز بشاشة LED حمراء عالية السطوع مقاس 22 مم مكونة من 6 أرقام، والتي يمكن قراءتها بوضوح حتى في بيئات الإضاءة القوية؛ يدعم تبديل الوحدة تنسيقات متعددة مثل كجم/جم/رطل/رطل.أونصة/ 斤 /pcs، تتكيف مع مختلف معايير الصناعة محليًا وعالميًا. توفر منافذ الاتصال خيارات متعددة مثل RS232، وWIFI، وEthernet، وشبكات 4G، مما يُسهّل ربط البيانات، سواءً للعمليات المستقلة أو للوصول إلى إنترنت الأشياء الصناعي.

· مجال بيع المنتجات الطازجة بالتجزئة :عند وزن الفواكه والخضروات في محلات السوبر ماركت، يمكنه طباعة الملصقات بالسعر والوزن والرموز الشريطية في الوقت الفعلي، مما يقلل من أخطاء التسجيل اليدوي ويحسن كفاءة سجل الدفع النقدي؛

· روابط التخزين والخدمات اللوجستية :أثناء دخول البضائع إلى المستودع وخروجها منه، يتم طباعة ملصقات لوجستية بشكل متزامن مع أرقام الدفعة والوزن الإجمالي ووزن العبوة والوزن الصافي، مما يسهل إدارة المخزون وإمكانية تتبعه؛

· سيناريوهات الإنتاج الصناعي :عند وزن نسب المواد الخام، فإنه يقوم تلقائيًا بإنشاء سجلات الإنتاج مع معلمات الصيغة، مما يوفر دعم البيانات لمراقبة الجودة؛

· سيناريوهات التشغيل المتنقلة :مثل شراء المنتجات الزراعية ووزن الاستكشاف الميداني، فإن مصدر طاقة بطارية الليثيوم مع وظيفة الطباعة المدمجة يتخلص من قيود الطاقة والمحيطية.

بصفتها علامة تجارية صينية متخصصة في أجهزة الوزن، حرصت JADEVER على مراعاة احتياجات المستخدم بدقة في التصميم التفصيلي لجهاز JWI-770P. بدءًا من مقاومة الدخل التي تزيد عن 10×10⁶ أوم لضمان نقاء الإشارة، وصولًا إلى مستوى حماية IP (يُرجى استشارة الشركة المصنعة لتحديد المستوى المناسب) وتصميم مقاوم للغبار والماء، وصولًا إلى تصميم مفاتيح بسيط وواضح (بما في ذلك مفاتيح ZERO tare وTARE وPRINT وغيرها من مفاتيح الوظائف)، تعكس كل تفصيلة مفهوم البحث والتطوير "التركيز على المستخدم".

اليوم، أصبح جهاز JWI-770P الجهاز المفضل لصناعات مثل تصنيع الأغذية، والمواد الكيميائية، والأدوية، والخدمات اللوجستية، بفضل مزاياه الثلاثية: "الوزن + الطباعة + إدارة البيانات". فهو ليس مجرد مؤشر وزن، بل أداة أساسية لا غنى عنها في التحول الرقمي للمؤسسات - فهو يقيس كل وزن بدقة، ويُبسط كل عملية باستخدام التكنولوجيا، ويترك إدارة الوزن تُودع الملل وتُدخل عصرًا جديدًا من الذكاء والكفاءة.

إذا كنت تبحث عن حل للوزن يجمع بين الدقة العالية والمرونة العالية والأداء عالي التكلفة، جاديفير JWI-770P مؤشر الوزن المدمج بالطباعة هو بلا شك خيارك الأمثل. تفضل بزيارة الموقع الرسمي للمنتج لمعرفة المزيد من التفاصيل الفنية وخدمات التخصيص، واستمتع بالدقة والكفاءة في آنٍ واحد!